|

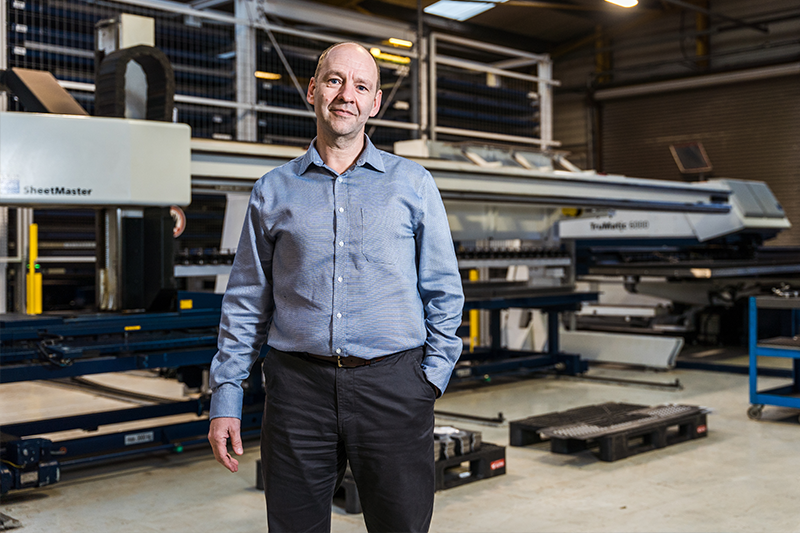

Leaving school, Alpha Manufacturing commercial director Robin Eley was wedded to the idea of a technical apprenticeship but his employer, Dorman Diesels, a subsidiary of GEC at that time, saw that Robin had a real commercial edge so encouraged him to take that route. Today, Robin is our commercial director and is passionate about developing long-term strategic partnerships with our customers and supply-chain partners. |

Robin picks up the story here: “I naturally felt comfortable in a technical world, but Dorman Diesels had other plans for me! I switched my BTEC in engineering to business studies and my career catapulted from that moment. Reflecting on that time the greatest opportunity really was retaining all the technical competency – the hands-on skills of diesel engine manufacturing through to crankcase machining and full engine assembly gave the me the confidence to progress my career in a commercial function with the backing of real technical know-how.”

From Dorman Diesels Robin moved to Hadley Industries where he would progress through the business to become a general manager in one of the firm’s specialist engineering divisions broadening his experience selling into overseas markets.

In 2002 Robin joined Alpha Manufacturing and it’s here Robin cites his greatest career achievements, as he explains: “From the start of my career I’ve really enjoyed the collaboration between sales and engineering – when you get it right and you work with a customer to engineer a solution, it’s incredibly rewarding. Throughout my career the greatest moments have always been when my role has directly interfaced with the engineering process and it’s this innate practice that makes Alpha Manufacturing stand head and shoulders above the competition.

“We have such an expansive range of customers and it’s incredibly rewarding to work in so many different sectors. While the customer base is vast, every project we touch shares the same high-precision engineering qualities. Still, to this day, the most rewarding part of my job is being involved in concept development though to prototyping and then on into repeat production, ensuring that cost saving ideas are built into the fabric of the initial design.”

Alpha Manufacturing has continued to invest in the very best machines and processes that continue to challenge traditional manufacturing methods. This ongoing investment has allowed the company to grow year on year completely eliminating any constraints on capacity. In summing up, Robin says this: “Looking back to 2006 when we relocated to our current Pasturefields’ site I would have never believed we’d fill it! And now, as we are on the brink of announcing significant expansion plans, we can look to the future with immense excitement as we continue to grow the business working with businesses looking for a trusted partner – not just a supplier.”