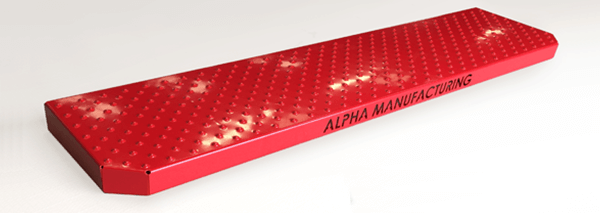

Stage One: Design

At Alpha Manufacturing, we manufacture a range of steps of tread plates for commercial vehicles and agricultural machinery. This step is variation of a product that we manufacture for one of our commercial vehicle customers.

Our design team begin by creating firstly a 2D drawing of the step, then a 3D CAD model. These will be signed off by our customer, usually along with a prototype sample. The models are then converted into programs (CAM) which tells the processing machine how to handle the part.

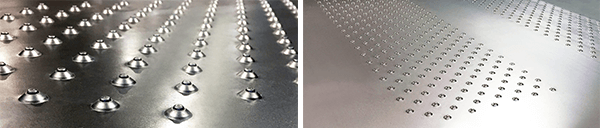

Stage Two: CNC Punching

The first process in the manufacturing of this step is CNC Punching. A sheet of 2.5mm CR4 (Cold Rolled Steel) material is loaded by the automated sheet-master tool.

A purpose made 934 step forming tool is selected by the tool changer and the machine begins to punch. The tread pattern is formed using a single hit from the tool as the punch bed moves the metal sheet along.

Tread plate forming using a Trumpf TruPunch 5000 machine:

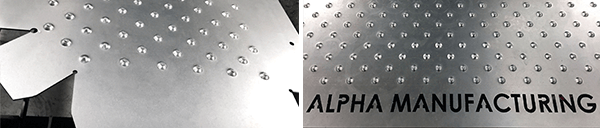

Stage Three: Laser Cutting

One the tread pattern has been punched the metal sheets are loaded into the laser cutting machine by an automated bed. The laser then cuts the step profile form the sheet along with custom lettering which is programmed to suit the customer.

Lines are etched onto the step to mark fold lines and slots are also cut to aid the welding process at a later stage. Once the Laser cutting is complete, a machine operator removes any waste material, leaving just a flat step profile.

Laser cut profiles, slots and etching using a Trump TruLaser 3030:

Stage Four: Folding

Next, the flat profiles are folded into shape using a press brake. An operator manually sets up the tools and programs the machine according to the instructions on the part drawing. He uses the etched fold lines as guidance before applying the bend.

After applying the fold, the operator measures to ensure the angle is correct and within tolerance.

Folding using an Amada Press Brake:

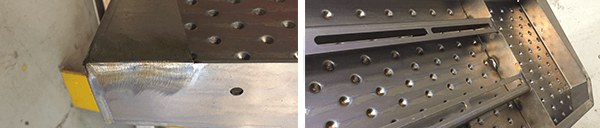

Stage Five: Welding

Once folded into shape, the seams are joined by welding. For this particular part, a MIG weld is used whereby a wire electrode is fed through a welding gun and an electric arc is formed between the wire and the metal workpiece. Resultant heat causes fusion of the metal.

The welder also attaches small inserts to the underside of the step using the slots previously cut on the laser machine (Slot and tab). These inserts are used to attach the step to the vehicle later. Once the welding is complete the welder linishes the part, removing any excess with a grinder to leave a smooth finish.

MIG (Metal Inert Gas) welding, slot and tab and linishing:

Stage Six: Powder Coating

The final production stage is to powder coat the product. Firstly, it is pre-treated with an alkaline solution, which is then rinsed off before another a specialised pre-treatment solution – Oxsilan 9810 is applied and once again rinsed off before the part is dried in an oven.

Now ready for coating, the part passes through an automated electrostatic spraying booth where the particular coloured powder is applied. The powder clings to the metal thanks to an electrostatic charge. Any areas missed by the spray booth are then touched up by a manual sprayer who also checks quality and coat thickness.

The part is then passed through another oven at up to 200oc at which stage the powder cures and bonds under the intense heat to create a smooth, glossy finish.

Automated powder coating line: