What's involved in the sheet metal design process?

This varies depending on the project and the type of product to be manufactured, whether it is a new design or a part that has been manufactured before. Often our customers will have some sort of drawing or design spec and depending on how detailed or accurate this is dictates our design team’s input.

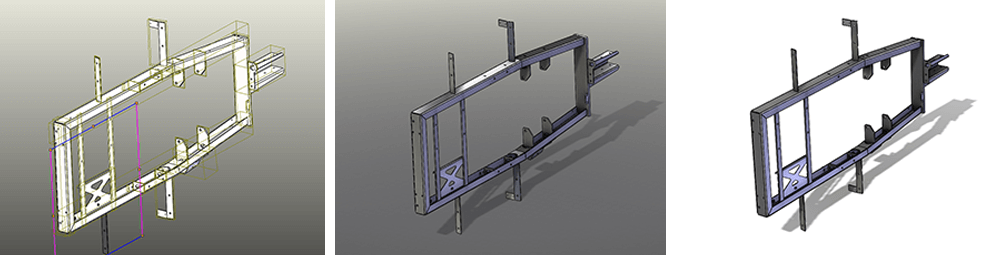

More often than not, our designers will draw or re-draw a product based on the customer spec. This allows our client to visualise the final product and make any design amendments prior to manufacture. At this stage, Alpha’s design team can also make recommendations on design alterations to improve manufacturing efficiency and therefore save money.

What software do the design department use?

Before any parts are cut, folded or punched our design team will create a CAD (computer aided design) component in a virtual 3D environment using three formats:

- DXF

- STEP

- SAT

This allows the design to be exported and sent between our team and the customer, with design modifications made before final sign off.

To do this, our designers use the latest version of Solid works to create, manipulate and output the 3D model product. It also allows design changes to be quickly made and presented back to the customer before manufacture. The time and cost benefits to our customers at this stage are considerable, bearing in mind that we manufacturer parts in batches of thousands or even tens of thousands.

The ability to be 100% confident of a design before manufacturer is priceless.

An example of CAD development:

What file types can our designers work with?

When receiving files from a customer our designers can work with various files but the most common are:

- STEP

- DXF

- DWG

- IGIS

- Parasolid

- Inventor

- solid edge

When outputting CAD models, designers will generally use one of the following:

- Solidworks

- IGIS

- STEP

What's involved in value engineering?

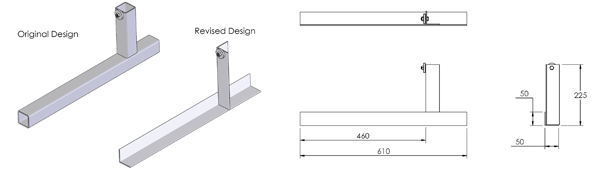

Often, our design department will work very closely with our NPI (new product introduction) team as well as the quality department, to re-engineer either a new design or existing product. We do this to either maximise efficiency in the manufacturing process or to make other cost savings. For example, by reducing material content, changing a process or making a component that was previously outsourced.

An example of value engineering an existing customer design:

Can the design team recommend materials?

Our designers work with various materials and have extensive knowledge of the advantages, disadvantages and general properties of each one. This is why they will often suggest a material change, perhaps to a lighter one. Or a different finish maybe for a part that will be used outside and needs a more resistant paint finish.